Floors for Dairy Processors

Silikal® Nationwide Flooring- 888.830.1404

-

Silikal provides an untold number of seafood processing flooring due to the extreme quality of the flooring as well as its non-porosity.

-

-

The Problem

The days of a milkman delivering bottles of milk, cream, and butter to your door may be long gone but Americans still love their dairy products, and look for the best and freshest product they can find. Who hasn’t reached into the back of the stock at the supermarket to get the carton with the latest expiration date?

For dairy processors, getting their product to market in a timely manner is important, but recent emphasis on HACCP, FSMA and keeping FDA happy, has mandated that these manufacturers look at their flooring as a potential source of Listeria and other pathogens, and take steps to eliminate flooring from the equation.

Years ago, many dairy facilities were built with brick floors. Over time, the pounding from traffic, the thermal shock from washdowns, and the chemical attack from cleaning chemicals destroys the grout between the bricks, allowing food acids and chemicals to collect on and attack the substrate below.

Quite a few factories still deal with this surface in many areas, continually patching the worst areas with epoxy – trying to prevent taking the area offline. It would take weeks to remove all the production equipment, the brick, and possibly a setting bed, and put it all back –no dairy can afford to be down for that long.

Resinous Flooring

Some dairies have tried overlaying the brick with cementitious urethane flooring. This product responds well to the thermal cycling but is so porous that food and CIP chemicals penetrate the pores of the flooring and work their way down to the brick and concrete underneath. In a survey taken in 2013, the average resinous floor installed in the food processing industry lasted LESS THAN 5 YEARS!

Additionally, both of these formulas require 24 hours [after installation is completed] to reach substantial curing and do not completely cure for 7 DAYS! Who can afford to shut down for that long? Most companies start back up long before curing has taken place, compromising the overlayment’s ability to perform per specification.

The Silikal® Difference

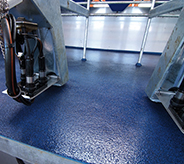

Silikal’s proprietary slip-resistant formula [similar in chemistry to Plexiglas] has no pores or pinholes. Therefore, nothing will penetrate the surface. This is why Silikal outlasts and outperforms every other floor in a food processing environment. We have customers with 25 year-old floors that look and perform like new!

Silikal flooring cures in one hour – at temperatures down to 0°F! This means that a Silikal installation can be fit into your schedule – often without loss of production – saving your company thousands!

Silikal floors are installed by business partners that have been field-trained by company employees. You can be sure that with Silikal, your floors will be properly installed to provide your company many years of trouble-free service – and we have a guarantee to back it up!

COLOR MIXING DESIGN TOOL

COLOR MIXING DESIGN TOOL

COLOR CHARTS + BLENDS

COLOR CHARTS + BLENDS

SAMPLE REQUEST

SAMPLE REQUEST

Silikal®is manufactured + sold in conformity to

Silikal®is manufactured + sold in conformity to

Avoid Costly Downtime

Avoid Costly Downtime