Marine Non Skid Coatings Set Sail

Marine Non Skid Coatings: Keeping Ocean Decks Everywhere Safe

If you currently have a boat or a ship, then you know how important marine non skid coatings can be. Even the sailors who are in the Navy are more than aware that it only takes one wave to hit wrong and in the wetness you may find someone going overboard! Mariners are only too conscious too, that true anti slip marine deck coatings need to be extremely durable as they are out in the elements, and depending on the use of the boat or ship, some marine non skid coatings should be adjustable when purchased and installed.

Boaters wish for undeviating totally homogenous materials, they have had it with non marine deck treatments consisting of fillers such as rubber flecks, actual beads, decimated walnut shells, or even sand! Fillers, mariners have learned the hard way, fall out and the walnut shells or whatever are gone, and thus all that’s left is a very unsafe decking that is almost impossible to clean. In addition boaters desire marine non skid coatings to be totally non-toxic, with absolutely no volatile solvents. They also desire a one-coat application and they wish to be able to have the coating cure within 24 hours.

Those who need the product are probably shaking their heads, for there is a product that delivers all that and actually cures in only one hour, which certainly makes those who live aboard their boats or ships extremely happy. That product is of course Silikal.

Cruise ships, large shipping vessels, and boat hulls have all fully benefited from Silikal’s waterproof floor coverings. First it’s the fact that Silikal’s protection enables the boat to take the ultraviolet rays of the sun, and the rain, the moisture that comes up from splashing, as well as dew. Fitting a boat with Silikal’s waterproof boat floor will save any boat owner money, since repairs and premature replacements of everything on a boat is so expensive.

It really does not matter how small your boat is, or how large your ship is, you will definitely be able to benefit highly from Silikal’s marine non skid coatings, also known as boat floor covering. All ships and boats share the conditions that make them deteriorate faster, thus all ships and boats should actually share in the bounties of Silikal’s most durable flooring.

Strangely enough, it seems that any boater seems to have boat restoration in his or her blood. The very vision of saving an older boat and then being able to restore her to her earlier glory is an appealing and also a very romantic one. Should you have that vision, be sure and look into Silikal for your marine non skid coatings!

Institutional Floor Finishes: Protection Guaranteed

Institutional Floor Finishes & Coverings

Mention the word institutional and many people automatically think of prisons and jails, and thus consider institutional floor finishes with bars attached. Strangely enough that view of institutional floor finishes is not far from reality. There are many institutions, including jails and prisons, which have benefited greatly from great floor finishes.

Your institutional needs may run into needing institutional floor finishes that can put up with the awful floor punishment of forklifts. Forklifts are about the worst thing that a floor has to deal with. First they are incredibly heavy, besides the increasingly heavy loads they carry around, and their large rubber wheels frequently leave scorch marks on the floor that they traverse upon. Forklift accidents are unfortunately very common, but one of the best things that a warehouse can do to avoid accidents including running into people, forklifts running into racks, columns, and even its own stored inventory is to make the warehouse cleaner and brighter. Warehouse lighting in general is rather poor as well as expensive to maintain but a bright floor color can do the job without continual costs.

One way to accomplish this is with a clean Silikal brightly colored floor. Institutional floor finishes can make a drab warehouse drabber in general as for some reason many warehouses think that their floor should be metal gray. Look at Silikal’s pictures of warehouses with light floors, and you can immediately spot the difference.

Perhaps you are considering institutional floor finishes because you have a meat packing plant. Such a plant will be very cold inside, and chances are that the final product is also kept at a frozen level. The location where the meat is cut and prepared will be slippery with grease and blood, thus that floor has to be completely slip resistant. Then too, inside the freezer sections of this plant, the floors there too must not be slippery and must be able to take the constant freezing temperature. Again, we have Silikal to the rescue, as it is the perfect answer to those two scenarios.

Suppose instead you are a hospital institution. Now it is superbly important for the floors to be scrupulously clean and in fact totally hygienic. Silikal is the perfect floor for a hospital as it is completely seamless as well as being non porous. Because of this factor, germs and bacteria have nothing to fasten onto. Nothing ever gets under a Silikal floor either! This makes them superbly easy to clean, and they are also completely resistant to stains, a fact that is important where iodine is frequently used, among other stain making liquids in a hospital.

No matter what your needs are for institutional floor finishes, Silikal has the perfect answer for you. Nothing beats Silikal!

Liquid Floor Tiles: An Inside Look

Liquid Floor Tiles Come Alive

The newest thing to hit floor tiles and flooring in general is liquid floor tiles. What happens with these is that walking on them moves colors around in the tiles. Perhaps put more poetically they actually create play as well as movements of light, which then stimulate the sensations of both atmosphere and nature. There are actually two different types of liquid floor tiles.

First to come out was the mono-chromatic liquid floor tiles. In effect these leave a retreating ray of various color tone rays within the memory traces of footprints left behind. What the bi-chromatic tiles do is to stimulate playing with colors as well as with forms of all kinds in an incessant and uninterrupted evolution.

As one walks, it comes as no surprise that the creators of these liquid floor tiles were obviously stirred by their memories of walking across green pastures or sandy beaches, which then left their marks directly upon nature in the form of their footprints. That particular feeling is just what the liquid floor tiles make you feel.

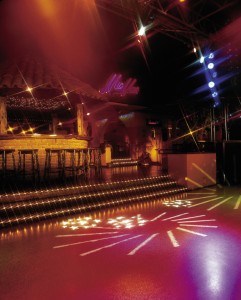

The liquid floor tiles are actually custom made, thus they can utilize any shape, any color combinations, and any size desired by the purchaser. The way that they are made is that they are actually filled with brightly colored, totally non-toxic liquids. This is what enables them to move and swirl in color when they are walked upon. Commercial usage such as bars, nightclubs, museums and even hotels where children gather have been the most common users of these tiles. Granted they are new, different, fun and very exciting at present.

Technically construction is rather simple, for it is 2 separate sheets of polycarbonate. The top of this tile has been treated so that it has anti-slip properties, and the bottom is actually used to act as shock-proofing. Then it is filled and encased in more polycarbonate. Each tile is about ¼” thick, and each of these tiles is individually tested before going out for use by having a 500 kg load for each square meter. Their reactions are best when applied at room.

As said these new liquid floor tiles are definitely new…thus the excitement of them will grow. It is obviously soft enough to leave foot “dents” into, and yet cannot be utilized where too much pressure will go upon it, and we have no idea how protective it will be to the concrete below it. Time will tell!

Non Skid Floor Finish Additive: The Added Protection Option

A Non Skid Floor Finish Additive For High Traffic Areas

Various floor finishes do not come with a non-skid floor finish additive. These are added in by the operator or at the factory before the product is taken to your location. Thus if you desire a non skid floor finish additive you’d best bring it up to the person who comes to give you your estimate. Not all flooring companies will even ask you if this is a necessity for you, which is truly unfortunate.

On the other hand there are numerous additives that can get added very simply to paint. Whether or not this will deliver a true non-skid floor finish is debatable though. Read the warranty that comes with the product. Chances are they are not responsible if it fails for any reason. You might as well not even add it to their paint. Disclaimers abound when you add a non-skid floor finish additive. For instance I have found some disclaimers that say that it will actually reduce the lifespan of the product! Then there is a further warning, that definitely made my heart sink, stating that one needs to hold onto any leftover paint due to the need for periodic maintenance re-coating.

Then there are the companies who will sell you “play sand,” or silica sand, and some even utilize polypropylene beads. The last thing you will wish to utilize on your floor finish is play sand. It is very rough, and will skin the knee of anyone who happens to fall on it. In addition, play sand is much too abrasive, it will in fact shred off your flooring. There are some who will also sell you decimated walnut shells to mix into your floor finish. Commonly utilized though is pumice which is a volcanic product. All of these various techniques require sustained maintenance however as they will actually decrease the lifespan by wearing away the very product used to protect!

The very best product available though in a non-skid floor finish additive is Silikal. When you are seeking true non-skid products because it really counts, then you will find that Silikal has been utilized for it’s non-skid properties in military installations, air hangars, parking decks, restaurants and bakeries, hospitals and medical offices, schools, manufacturing plants, high rise buildings and a myriad of other places that knew that non skid properties in their floors was not to be passed over or denigrated!

Silikal is so serious about its non skid floor finish additive that it will actually offer degrees of non-skid to its flooring. Thus Silikal non-skid floors are actually designed to withstand all kinds of wear and tear and do this all without any warping, splitting or cracking or degenerating!

Interior Concrete Floor Sealer Systems: A Black Hat Top Coat

An Interior Concrete Floor Sealer Designed to Impress

Any interior concrete is going to need an interior concrete floor sealer. The reason is that although concrete is hard, it’s actually rather delicate as hard things go. Interior concrete floors left unsealed will develop dust, and often have corners break off. In the worst case scenarios, cleaning plain old concrete gets old, and every time water is put on it, dirty water seeps through the concrete to make bigger problems eventually. There’s a saying that many people are taught in school about “the unexamined life is not worth living” said Socrates, but to paraphrase good old Socrates, I say that “the unsealed concrete floor is not worth having!”

The reasons are many why this is so. Putting down an interior concrete floor sealer will actually prolong its life, and will actually enhance as well as preserve its appearance too. There are of course hundreds of different floor sealers, some good, some bad, some just so-so and one superbly great one!

First, you’ll run into acrylic sealers, either water based ones, or solvent formulations. These work pretty well, and will definitely make your concrete beautiful and shiny for a while. That’s the catch – for a while. They will need to be specially maintained with more than a few coats of floor finish, or wax.

Next is the polyurethane interior concrete floor sealer. This is thicker than the simple acrylic sealer, thus has a higher resistance to chemicals as well as abrasion. Available in both solvent and water based types and generally they offer a range of sheen. Not for excellent resistance to chemicals nor abrasion though.

Now come epoxy sealers. These do produce an abrasion resistant finish, they are long-wearing and quite hard and do protect your concrete surface. Most of them are very water repellent. Unfortunately chances are that they will yellow if exposed to UV rays and shielding a flooring from UV is dependent on the space and exterior light access.

All sealers will not meet your current Federal and local regulations with regard to VOCs either. For example, xylene is a very common solvent frequently found in concrete sealers. It unfortunately produces VOC’s, or volatile organic compounds which can be harmful to elderly, immune deficient, and small pets.

Now we come to Silikal, yet another type of interior concrete floor sealer. First Silikal has absolutely no VOCs, ever. All of the Silikal products will deeply enrich the color intensity of the concrete if it was dyed or stained, or you may choose a seemingly unending choice of colors to bring incredible beauty to your floors. In return to making your floors superbly easy to maintain and clean, you will also be permanently blocking the penetration of stains, chemicals, grease, oil, and all manner of dirt. Neither water nor chlorides can intrude into your concrete either with Silikal. Protection against wear and any abrasion is a given, as Silikal floors outlast the buildings they are put into and they do not yellow!